Description

- Mesh Type: Ferruled

- Ferrule Type: Stainless Steel

- Space Between Ferrules: 60mm

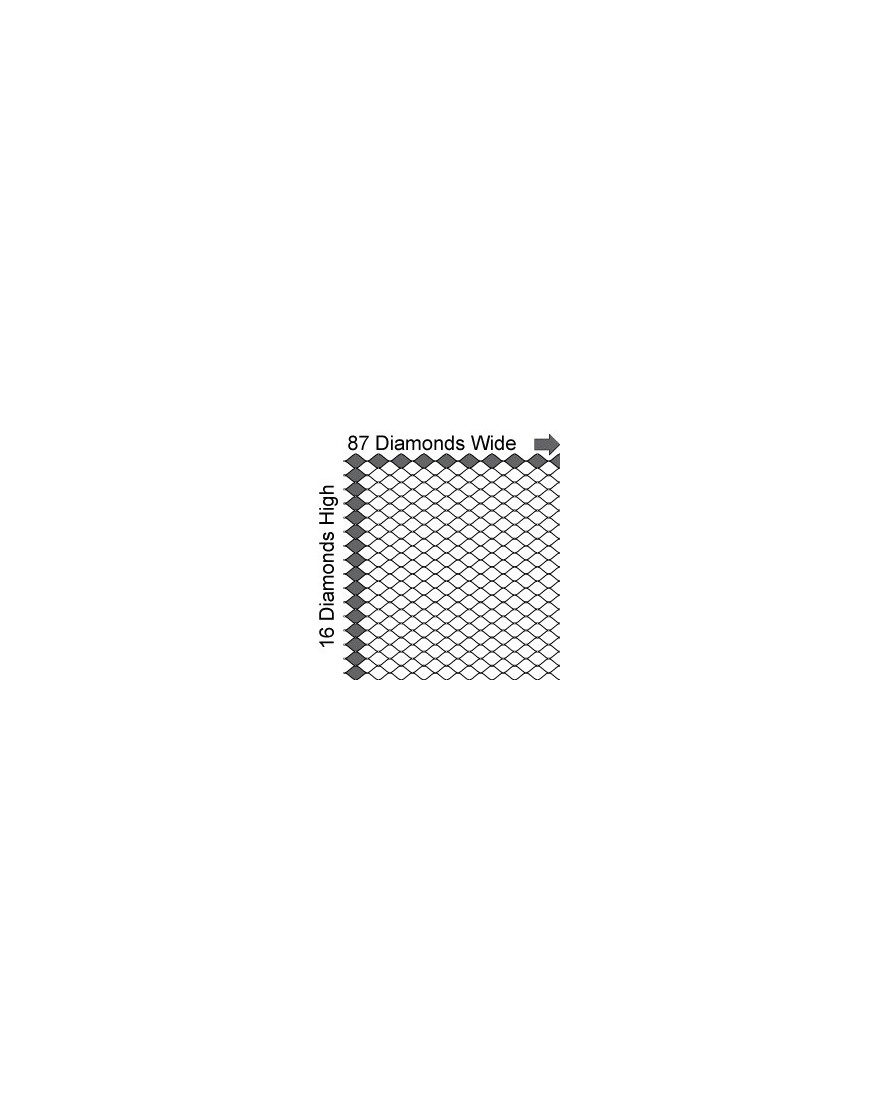

- Diamonds: 16 high x 87 wide

- Approximate Diamond Height: 2″ – 2 1/4″ / 51mm – 57mm

- Approximate Diamond Width: 4 1/2″ – 4 3/4″ / 114mm – 120mm

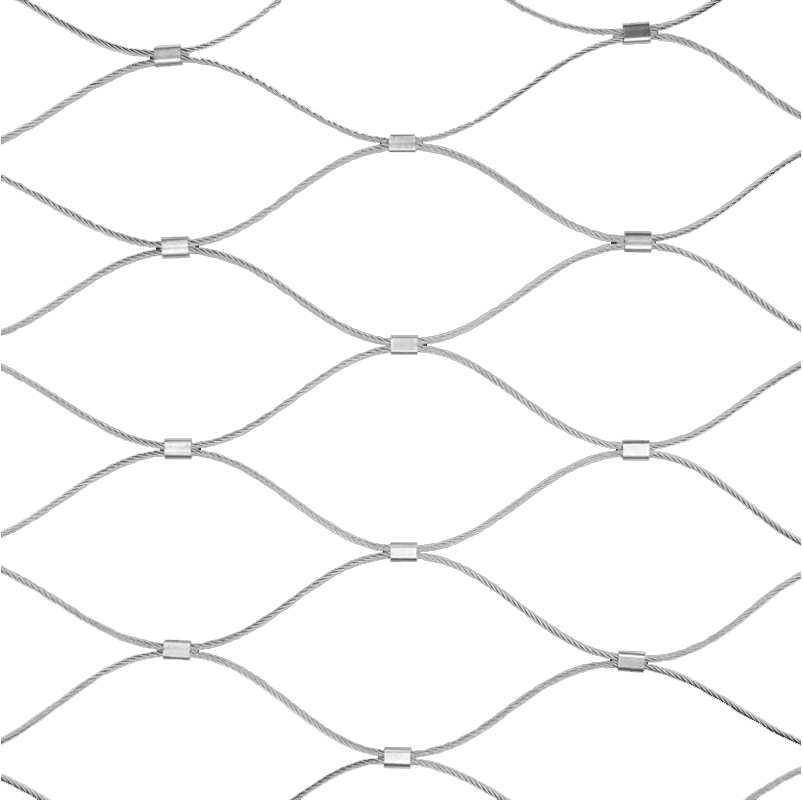

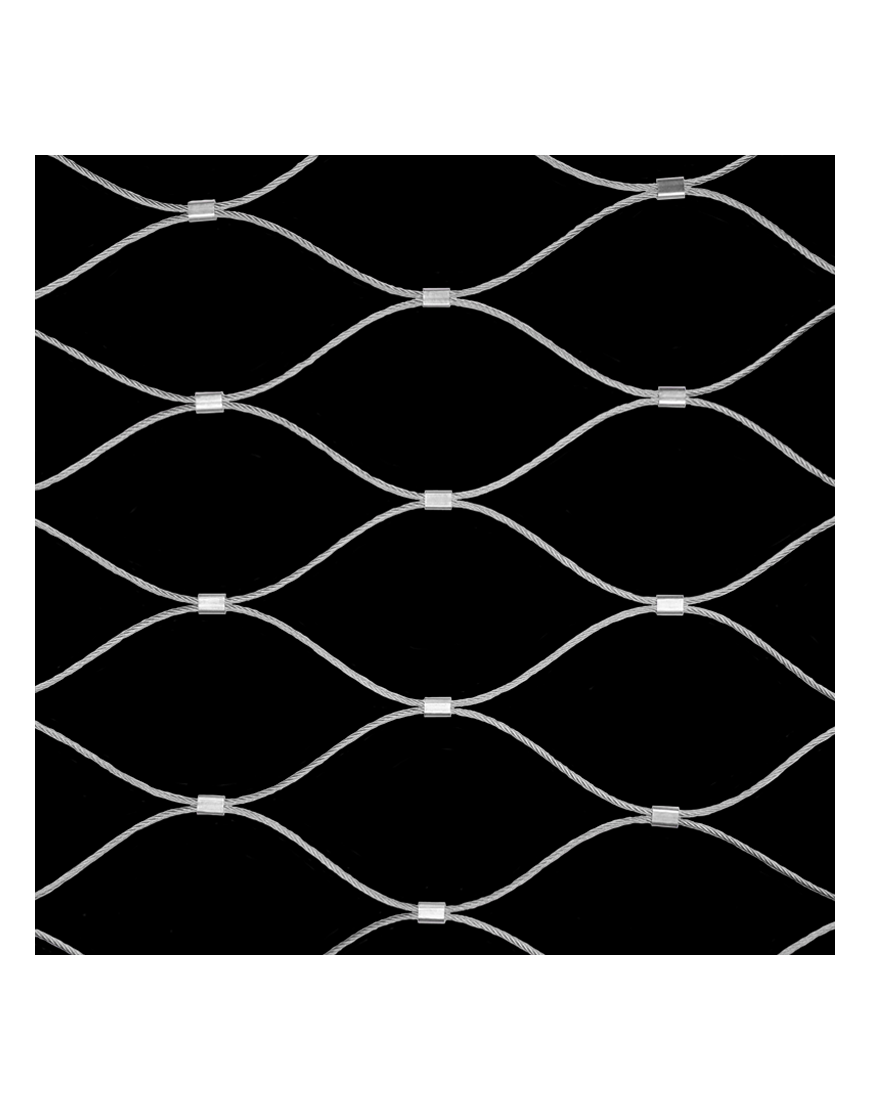

Luna Architectural Products offers high quality wire net rolls made of either 1.5mm or 2.0mm gauge stainless steel 7×7 cable. The cables are assembled into a net (web) using stainless steel ferrules that are crimped 60mm apart. When these assemblies are expanded they create an appealing diamond pattern that offers considerable strength in an unobtrusive design.

The exact dimensions of the diamond shape are determined by the amount the assembled cables are expanded. The most common diamond shape is achieved when a 60 degree angle exists between two adjacent cables. Other variations of this diamond shape can be used as either required or preferred for each application.

EXPAND web net is made from 7×7 316 Stainless Steel cable

Wires crimped together using ferrules, shown unexpanded

Expanded to a 60 degree angle, a common diamond shape is formed

Expanding to a 40 or 20 degree angle changes the look and characteristics

Rolls

-

- 14 diamonds wide x 87 diamonds long (Approx. 32’9″/10m long expanded)

-

- 15 diamonds wide x 87 diamonds long (Approx. 32’9″/10m long expanded)

-

- 16 diamonds wide x 87 diamonds long (Approx. 32’9″/10m long expanded)

The dimensions of each of these rolls will vary and be determined by how much each roll is expanded.

Custom roll sizes are available, please let us know what you need.

Custom cutting of the rolls to the sizes required for your project is available, please contact us to find out more information.

Any dimensions of expanded rolls provided to you on this website are for your reference only and should be confirmed during the fabrication process.

Rail Clips

Each roll comes with stainless steel Rail Clips attached to both the upper and lower sides of the roll along its length. These rail clips will be used along with Fastening Wire to attach the rolls to the upper and lower horizontal rails of the frame which it is being installed into. Rail clips are also available to be purchased separately, by the piece.

End Fittings

As you will be cutting the rolls down to size as required for your project, you will need to select one of our two types of end fittings to be used on both the left and right sides of the cut web net sections.

These are the two types of end fittings you can use:

1. Squeeze Clip End Fittings

The Squeeze Clip End Fittings are the fittings that come attached to the full rolls when purchased. Two adjacent wires are both inserted into the open end of the fitting which is then crimped securing both cables inside. The Squeeze Clip End Fitting is then ready to be attached to the horizontal frame components using the appropriate Fastening Wire.

2. Clip Assembly End Fittings

These end fittings are made up of three parts assembled together to create the end fitting assembly. First is the factory crimped ferrule located at the end of the section cut and sized for the panel being fabricated. Next, the End Assembly Outer Clip is slid over the ferrule and its pair of adjacent cables. Then the End Assembly Inner Clip is slid over the factory crimped ferrule. Finally the End Assembly Outer Clip is slid over the Inner Clip. This End Assembly is now ready to be attached to the vertical frame element using the appropriate Fastening Wire.

Fastening Wire & Fastening Clips

The Fastening Wire is woven around the perimeter frame components and inserted into the clips found along the edges of the wire net rolls.

The 7×7 Fastening Wire is available in 1.5mm or 2.0mm gauge cable and is sold by the foot.

The Fastening Wire can be crimped to itself using Fastening Clips

Reviews

There are no reviews yet.